This story plays out a bit like a science fiction novel, but it happens to be news.

In the past, when we praised someone for being smart, we would say, “It’s not rocket science.” The implication was that building rockets represented the ceiling of human intelligence—a privilege reserved for a select few geniuses burning the midnight oil over blueprints.

But in June 2024, a company in Dubai called LEAP 71 used a computer and a pile of code to deliver a resounding slap to this “ceiling.”

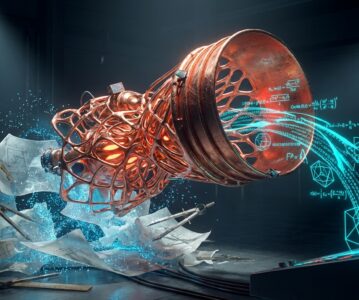

Their AI model, Noyron, autonomously designed a liquid rocket engine with 5kN of thrust with zero human intervention. Even more outrageous is that the entire process—from design generation to 3D printing and successful ignition—took less than two weeks. And the time it took to generate this entire set of complex geometric structures on a computer? Less than 15 minutes.

This isn’t just a matter of being “fast”; this is a dimensional strike. While we are debating whether AI can paint or write poetry, it has quietly reached for the jewel in the crown of human industry.

01 The Death of the Draftsman

Let’s first understand the significance of this “ignition.”

In traditional aerospace giants, what is the process for designing a rocket engine? It involves a room full of balding engineers staring at CAD (Computer-Aided Design) software, drawing day and night. How thick is the combustion chamber wall? How should the cooling channels run? What is the injector aperture size? Behind every parameter lies countless meetings, calculations, simulations, and complete do-overs.

What did LEAP 71 do? They completely skipped CAD.

Noyron isn’t “drawing”; it is “weaving logic.” Founders Lin Kayser and Josefine Lissner didn’t teach the AI to draw a cylinder; instead, they wrote the laws of physics, fluid dynamics formulas, thermodynamic limits, and the manufacturing constraints of 3D printers entirely into code logic.

This seemingly complex metal structure is actually the optimal solution calculated by AI; not a single line was drawn by a human.

To put it plainly, traditional engineers are “sculpting,” while LEAP 71’s AI is “growing.”

This explains why they dared to use copper to print the engine. Anyone who knows materials knows that copper has excellent thermal conductivity, but its melting point is only around 1083°C. The internal combustion temperature of this machine, however, reaches up to 3000°C.

This is like trying to keep a piece of chocolate intact inside a steel blast furnace. The only solution is to have coolant flow frantically within the combustion chamber walls to carry away the heat.

The cooling channels designed by Noyron are shockingly thin (0.8mm) and extremely complex. If a human engineer had to draw these intertwined vessels in CAD, they would likely smash their mouse halfway through. But the AI has no temper; it instantly calculated the optimal flow distribution.

The result? The surface temperature was kept strictly below 200°C. The copper didn’t melt, the rocket flew, and the engineers’ glasses shattered on the floor.

02 Beyond the Black Box

There is a blind spot here that is easily overlooked.

Whenever we hear “AI design,” our first reaction is often “Generative AI” like Midjourney or ChatGPT. You feed it a pile of images, and it calculates a probability to produce an image that looks like a rocket. This is called a “Black Box”; you have no idea why it drew it that way, and if you built it, it would probably explode.

But LEAP 71 is playing with “Computational Engineering,” which is a completely different species.

Noyron isn’t “guessing” shapes; it is “solving” equations.

The core of this AI isn’t a probabilistic black box of neural networks, but a transparent “Glass Box.” Every bend in the pipe, every hole it generates, is supported by strict physical formulas. It knows that “if the pressure is high here, the wall thickness must increase”; it knows “if the material is copper, the cooling flow rate must reach X.”

This is the most terrifying part of this event: It outputs not pixels, but physical truths.

Many worry that AI will confidently spout nonsense. But in the field of Computational Engineering, the cost of nonsense is failing physical simulation. LEAP 71’s success proves that AI can not only imitate human “creativity” but also strictly adhere to the “rules” of the real world.

Of course, it isn’t perfect. Testing revealed that the resistance in the cooling channels was higher than expected because the 3D-printed copper surface was too rough. You see, the AI calculated the fluid dynamics correctly but didn’t account for the “temperament” of the printer in the real world. It’s like a genius mathematician who calculated the perfect run but didn’t anticipate a pebble on the track.

03 The Paradigm Shift

If we widen our view, you’ll realize that aerospace manufacturing is undergoing a quiet earthquake.

- Old Space: Like NASA’s supplier system. Design cycles are measured in “years,” manufacturing in “months.” Once a design is set, changing a screw involves a six-month process.

- New Space 1.0: Like Relativity Space. They use giant robotic arms to 3D print rockets, but this is more of a manufacturing innovation; design still relies primarily on humans.

- Computational Engineering (The LEAP 71 Way): The boundary between design and manufacturing has vanished.

Compare the data:

- Time: Traditional months vs. AI’s 15 minutes.

- Iteration: Traditional requires redrawing blueprints vs. AI changing a parameter and auto-regenerating.

- Cost: Traditional abandons complex structures due to machining inability vs. AI specifically choosing complex structures (since 3D printing doesn’t care how weird the shape is).

This is like taking a Gatling gun to a war of muskets lined up in rows. LEAP 71’s thruster might not match SpaceX’s Raptor engine in thrust yet, but its iteration speed is exponential.

As long as the data from this test (like the lesson about surface roughness) is fed back into Noyron, the next generation engine it generates will immediately correct the issue. While human engineers need to accumulate ten years of experience, AI might only need to run data regression overnight.

04 Engineers: Dusk or Dawn?

The more I think about this, the more terrifying it becomes.

If AI can truly handle all geometric construction and physical verification, what is left for human engineers?

Some say “decision making.” But Noyron can already make decisions automatically based on high-level commands like “thrust” and “fuel type.”

Some say “innovation.” But looking at that complex flow channel structure generated for extreme cooling—something humans would never think of—are you sure humans really understand innovation better than AI?

I’m also thinking that future aerospace companies might not need design teams of hundreds of people, but just a few “Architects” who understand physics and code. They will no longer draw; they will write “constraints.”

But there is a huge concern here: The boundary of explainability.

This engine is simple, just a small 5kN unit. If, in the future, AI designs a monster with 500 tons of thrust and a structure so complex that even the most senior engineers can’t understand it, would we dare to ride it?

When design complexity exceeds the threshold of human understanding, do we choose to blindly trust the AI’s “perfect logic,” or do we shelve it because we “don’t understand” it? This might be the biggest question in tech ethics for the next decade.

05 Reflections

Looking at the dazzling Mach diamonds on the test stand, I suddenly felt a bit sentimental.

Once upon a time, every elegant curve on a rocket nozzle was a masterpiece deliberated over repeatedly by an engineer using a T-square and pencil on a drafting board. That was the romance of the industrial age, a crystallization of human rationality and aesthetics.

Now, that romance has been compressed into a few lines of cold code and mass-produced in 15 minutes.

But maybe this isn’t a bad thing. When AI takes over the tedious, boring work of “drawing” and “verifying,” humans can finally free up their brains to think about grander propositions:

For example, riding this AI-designed spaceship, which star should we visit?

After all, no matter how smart AI gets, it will never understand why humans always want to see the scenery on the other side of the mountain.

References: